The insulation cladding industry is undergoing rapid advancement as organizations seek long-lasting protection, improved safety, and higher energy efficiency. At Nextera Insulations, we observe emerging trends that are redefining how industries protect their thermal systems. Cladding is no longer just a protective shell—it has become an essential engineering component supporting sustainability and system reliability.

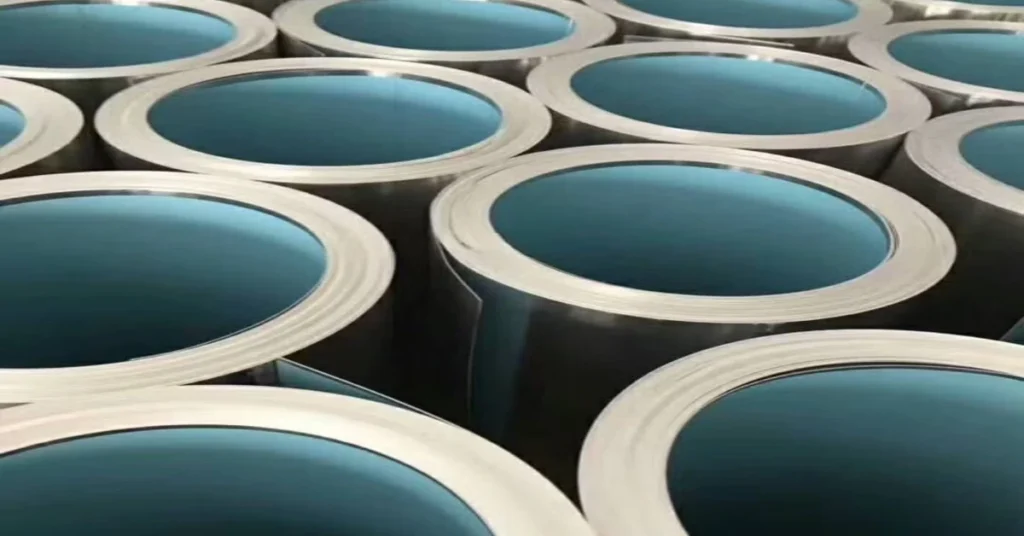

1. Moisture-Barrier Jacketing Becoming the Standard

Corrosion under insulation (CUI) remains one of the most costly industrial problems. This has accelerated the shift toward moisture-barrier-lined aluminium jacketing, which offers:

- Superior corrosion resistance

- Strong moisture protection

- Longer insulation life

- Better performance in humid climates

This barrier technology enhances system durability and minimizes long-term maintenance.

2. Lightweight, High-Strength Materials in Demand

Modern industries prioritize materials that deliver strength without adding extra load. Aluminium jacketing fits these requirements due to its:

- Lightweight nature

- High corrosion resistance

- Installation ease

- Compatibility with HVAC and industrial systems

Advancements in aluminium alloys are making cladding more durable than ever before.

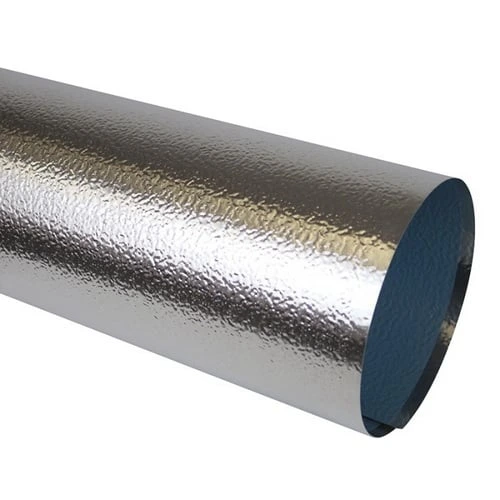

3. Embossed Finishes for Aesthetic and Performance Benefits

Embossed aluminium and stainless steel jacketing is now widely chosen because it provides:

- Better scratch resistance

- Reduced glare

- A cleaner appearance

- Less visible surface damage

The embossed pattern also helps installers handle material more efficiently.

4. Growth of Pre-Fabricated Cladding Components

Industries with complex pipe networks increasingly use pre-formed cladding fittings, including elbows, tees, reducers, and end caps.

Benefits include:

- Faster installation

- Improved accuracy

- Reduced site waste

- Long-term sealing integrity

Pre-fabricated pieces ensure consistent quality across entire systems.

5. Sustainability and Energy Efficiency as Key Priorities

Companies worldwide are investing in solutions that reduce energy consumption and environmental impact. Modern cladding:

- Helps insulation maintain thermal resistance

- Reduces heat loss

- Supports sustainability goals

- Lowers operating costs

Recyclable materials like aluminium and stainless steel further enhance environmental performance.

6. Upgraded Fasteners and Securement Systems

New fastening systems are designed to withstand vibration, temperature changes, and corrosive environments. These include:

- High-tensile stainless-steel bands

- Corrosion-resistant rivets

- Enhanced sealing mastics

- Expansion-friendly fastening systems

These improvements significantly extend cladding lifespan.

7. Introduction of Smart Monitoring Technologies

Digital tools and smart sensors are slowly entering the insulation field. These technologies help monitor:

- Moisture levels

- Temperature fluctuations

- Early signs of corrosion

They support predictive maintenance and reduce expensive downtime.

Conclusion

Industrial insulation cladding is moving toward more advanced, efficient, and durable solutions. Moisture-barrier jacketing, pre-fabricated fittings, advanced fasteners, embossed finishes, and smart monitoring systems are setting new industry benchmarks.

Nextera Insulations continues to support projects with high-quality materials that meet these modern demands and ensure long-term system protection.

Frequently Asked Questions

1. What is industrial insulation cladding?

Industrial insulation cladding is the outer protective layer installed over insulation systems. It protects insulation from moisture, mechanical damage, UV exposure, and corrosion while helping maintain thermal efficiency in industrial and HVAC systems.

2. Why is moisture-barrier jacketing important?

Moisture-barrier jacketing helps prevent water ingress, which is the primary cause of corrosion under insulation (CUI). By blocking moisture, it extends insulation life, reduces maintenance costs, and improves system reliability, especially in humid environments.

3. What are the benefits of aluminium jacketing?

Aluminium jacketing is lightweight, corrosion-resistant, easy to install, and highly durable. It is widely used in industrial, HVAC, and piping systems due to its excellent performance and long service life.

4. What does embossed aluminium jacketing mean?

Embossed aluminium jacketing features a patterned surface that improves scratch resistance, reduces glare, and hides minor surface damage. It also provides better grip during installation and offers a cleaner, more professional appearance.

5. How do pre-fabricated cladding components improve installation?

Pre-fabricated components such as elbows, tees, reducers, and end caps are factory-made for accuracy. They reduce installation time, ensure better sealing, minimize material waste, and provide consistent quality across the insulation system.

6. Is insulation cladding environmentally friendly?

Yes. Modern insulation cladding materials like aluminium and stainless steel are recyclable. Proper cladding also improves energy efficiency by reducing heat loss, which lowers energy consumption and supports sustainability goals.

7. What fastening systems are used in industrial cladding?

Common fastening systems include stainless steel bands, corrosion-resistant rivets, sealing mastics, and expansion-friendly fasteners. These systems are designed to handle vibration, temperature variations, and harsh industrial conditions.

8. How does insulation cladding help with energy efficiency?

Cladding protects insulation from damage and moisture, allowing it to maintain its thermal performance. This reduces heat loss or gain, lowers energy costs, and improves overall system efficiency.

9. What are smart monitoring technologies in insulation systems?

Smart monitoring technologies use sensors to track moisture levels, temperature changes, and early corrosion indicators. These tools help detect issues early, enabling predictive maintenance and reducing unplanned downtime.

10. How does Nextera Insulations support modern insulation cladding needs?

Nextera Insulations provides high-quality insulation cladding materials designed to meet current industry standards. The focus is on durability, safety, energy efficiency, and long-term system protection for industrial applications.