nextera

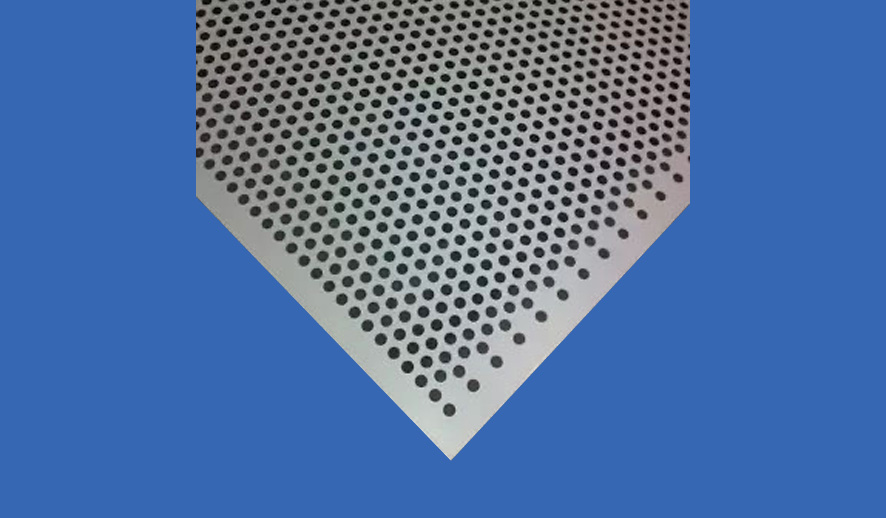

Perforated Sheets

Perforated sheets are a necessary part of industrial insulation systems, specifically insulation systems involving thermal, acoustic, and mechanical performance. Perforated sheets can be a thin metal sheet (usually stainless steel, aluminum or galvanized steel) with holes or patterns spaced at regular intervals. Sheets and perforation are not always aesthetic in insulation. Perforated sheets in insulation act as retainers, protectors, and enhancers of acoustic & thermal performance in industrial systems.

Applications in Industrial Insulation

1. Acoustic Insulation (Noise Control)

- Perforated sheets are often used in soundproofing lining of ducts, turbines, exhausts, and enclosures.

- Sound waves can enter the holes in the perforated sheet and pass into the insulation material (e.g., mineral wool, ceramic fiber) and the energy is absorbed resulting in a reduction in sound level.

2. Thermal Insulation (High Temperature Systems)

- For thermal insulation purposes in furnaces, boilers, and power plants, perforated sheets are used as retainers or jacketing to retain the insulation.

- They allow moisture or gases to escape while protecting the insulation material from mechanical damage.

3. Cryogenic & Cold Insulation

- In LNG, refrigeration, or low-temperature systems, perforated sheets are used in multi-layer insulation systems to reduce heat transfer while maintaining stability.

4. Mechanical Protection

- Perforated sheets provide a solution to protect fragile insulation (fiberglass, mineral wool, or aerogel blankets) from the elements, vibrations, or stress, while providing ventilation.

Typical Specifications

- Materials: SS304, SS316, Galvanized Steel and Aluminum

- Thickness: 0.5 – 1.5 mm (standard gauge for insulation cladding/retainers)

- Hole Diameter: 1 mm – 10 mm (as required by acoustics/ventilation hydration)

- Percent Open Area: 20% – 50% (defined by design)

- Patterns: round holes (most common), slots or customized

Benefits

- Sound absorption (if used in conjunction with mineral wool or acoustic blankets)

- Lighter weight than a solid sheet

- Ventilation allows moisture to escape and avoids condensation and trapping of water

- Durability & mechanical strength to retain insulation materials

- Fire resistance when using metals like stainless steel

Frequently Asked Questions

1. What are perforated sheets used for in insulation systems?

Perforated sheets are mainly used as retainers, protectors, and performance enhancers in industrial insulation systems. They support acoustic insulation (noise control), thermal insulation in high-temperature systems, cryogenic applications, and mechanical protection for fragile insulation materials.

2. What materials are commonly used for perforated sheets?

Nextera perforated sheets are manufactured using SS304, SS316, galvanized steel, and aluminum. The choice of material depends on the operating environment, corrosion resistance, fire resistance, and design requirements of the insulation system.

3. How do perforated sheets improve acoustic insulation?

When used with mineral wool or acoustic blankets, perforated sheets allow sound waves to pass through their holes into the insulation material, where the energy is absorbed. This significantly reduces noise levels in ducts, turbines, exhaust systems, and enclosures.

4. What are the standard specifications of perforated sheets?

- Thickness: 0.5 – 1.5 mm (standard gauge)

- Hole Diameter: 1 mm – 10 mm (based on acoustic/ventilation needs)

- Open Area: 20% – 50% (defined by design)

- Patterns: Round holes (most common), slots, or custom designs

5. What are the benefits of using perforated sheets in insulation?

Perforated sheets offer several benefits:

- Sound absorption for noise control

- Lightweight design compared to solid sheets

- Ventilation to prevent condensation and trapped moisture

- Durability & strength to retain insulation materials

- Fire resistance, especially when using stainless steel grades like SS304/SS316

Get in Touch

Enhance your insulation system’s thermal, acoustic, and mechanical performance with Nextera Perforated Sheets. Our products are engineered for durability and precision across industrial, marine, and energy sectors.

Location: Dubai, United Arab Emirates

Phone: +971 4 2633071

Email: sales@nexterainsulations.com

Website: www.nexterainsulations.com

Enquire Now

Have Questions or Ready to Get Started? Reach Out to Us Today — We're Here to Help!