nextera

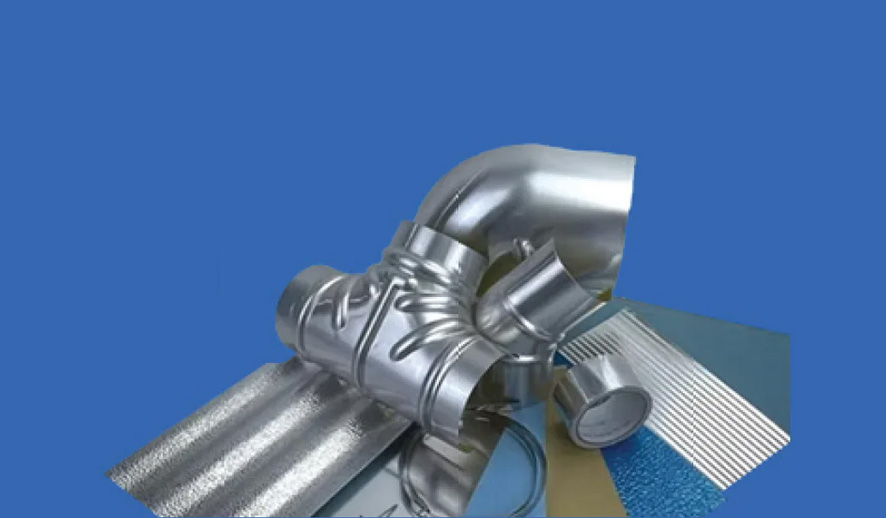

Aluminum Jacketing & Cladding

High-Performance Industrial Insulation Protection Cladding

Nextera Insulations, based in Dubai, provides high quality Aluminum Coils , Sheets and Rolls with Moisture Barrier, Mill Finish, Stucco Embossed, Corrugated sheets. Aluminum Jacketing & Cladding is a critical cladding option that safeguards thermal insulation systems from weather exposure, corrosion, and mechanical abuse. Designed to be durable and provide long-term performance, our aluminum jacketing extends insulation life and enhances energy efficiency in various industrial processes. The use of insulation in harsh industrial environments is only complete if it is accompanied by the right jacketing and that is exactly where Aluminum Alloys 3003 & 3105 are they best fit.

What Is Aluminum Cladding with Moisture Barrier?

Moisture-barrier aluminum cladding is a weather-tight outside layer applied above insulation systems. It is a premium-quality aluminum coil coated on the inside surface with polysurlin moisture-barrier. The barrier offers total moisture penetration resistance and thus minimizes corrosion under insulation (CUI) hazard, particularly in wet coastal or chemical conditions.

Nextera’s aluminum cladding is perfectly used on pipelines, tanks, vessels, and ductwork, giving a clean and durable finish—ideal for industrial and similar humid environments.

Key Features

- Corrosion Resistance: The inner barrier to moisture prevents the insulation from coming into direct contact with metal substrates, minimizing the chances of corrosion and rust, especially in the external or marine climate.

- Durable and Sturdy: Since it is produced from high-grade aluminum alloys, the cladding is marked by enhanced strength, weatherability, and physical protection for insulation systems.

- Energy Efficient: Aids as secondary thermal barrier, maintaining process temperature retention and reducing heat loss.

- Weather and UV Resistant: Formulated for long-term use outside, such as exposure to harsh environmental conditions of sunlight, rain, and industrial fumes.

- Lightweight and Simple to Install: Aluminum is easy to manufacture, cut, and install, reducing on-site labor time.

- Flexible Specifications: Available in an assortment of thicknesses, widths, and finishes to accommodate project specifications, i.e., smooth and stucco-embossed finishes.

Types of Moisture Barriers and Coatings that Are Available

- Polysurlyn Moisture barrier

- Polykraft Moisture barrier

- PVDF Coating

- PE Resin Coating

- Pre-Painted coils in accordance with RAL

Applications

Our aluminum coil with moisture barrier is applied in various industrial and commercial uses:

- Piping cladding for thermal insulation in vessels and pipes

- Insulation of HVAC system ducts and equipment

- Chemical plants and refineries

- Power generation and processing stations

- Marine and offshore platforms

- Oil and gas infrastructure

Why Choose Nextera Insulations?

Here at Nextera, we bridge material science and practical engineering to provide consistent thermal protection systems. Our Aluminum Jacketing & Cladding is designed to suit international standard of ASTM for reliable quality to all industries.

We provide expert advice at all levels—from product choice to end installation—and are dedicated to providing environmentally friendly, corrosion-resistant solutions that maximise the life of your insulation system and minimize maintenance costs

Your Partner of Choice in Insulation Cladding

Nextera’s Aluminum Jacketing & Cladding is more than just a protective layer—it’s a smart investment in performance, efficiency, and safety. Whether you’re insulating a power plant, a petrochemical facility, or HVAC systems in a commercial building, our cladding systems offer unmatched protection and peace of mind.

Frequently Asked Questions

1. What is the purpose of aluminum jacketing in insulation systems?

Aluminum jacketing acts as a protective outer layer for insulation, shielding it from weather, mechanical damage, and corrosion. It ensures the insulation system lasts longer, improves energy efficiency, and reduces maintenance costs.

2. Why is a moisture barrier important in aluminum cladding?

A moisture barrier such as Polysurlyn or Polykraft prevents direct contact between the insulation and the metal surface. This minimizes the risk of corrosion under insulation (CUI), especially in humid, coastal, or chemical plant environments.

3. What types of finishes are available for Nextera’s aluminum jacketing?

We offer a range of finishes including mill finish, stucco embossed, corrugated sheets, and pre-painted coils in RAL colors. These options provide flexibility for both performance and aesthetics.

4. Where can aluminum jacketing with moisture barrier be used?

It is widely used for pipelines, tanks, vessels, ductwork, HVAC systems, chemical plants, power generation stations, refineries, marine environments, and oil & gas facilities.

5. What makes Nextera Insulations different from other suppliers?

Nextera combines advanced material science with practical engineering expertise. Our aluminum cladding meets ASTM standards, ensures high corrosion resistance, and is tailored to meet the demands of harsh industrial environments, backed by expert consultation and support.

Get in Touch

Looking for the right aluminum jacketing and cladding solution for your project?

Our team of experts is here to help you choose the best material specifications and guide you through installation support.

Call: +971 4 2633071

Email: sales@nexterainsulations.com

Visit: www.nexterainsulations.com

Enquire Now

Have Questions or Ready to Get Started? Reach Out to Us Today — We're Here to Help!