nextera

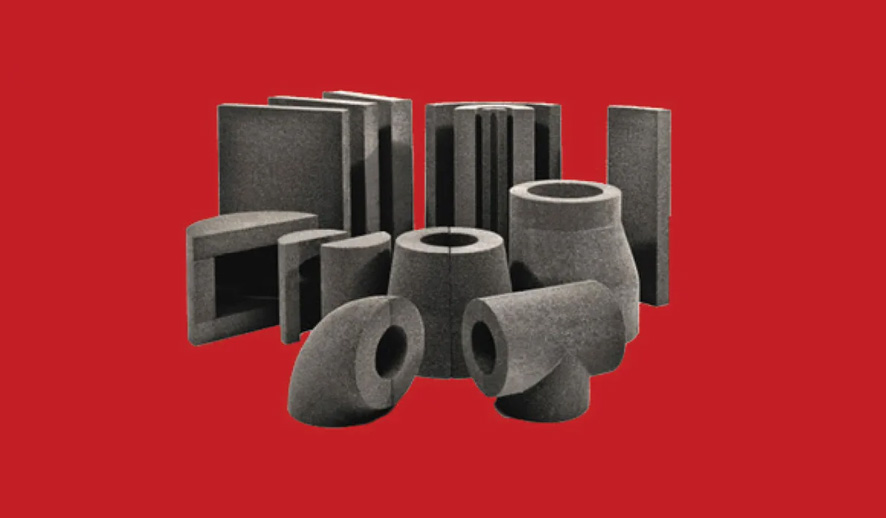

Cellular Glass Pipe Sections & Boards – Rigid, Durable, and Fire-Resistant Insulation

At Nextera Insulations, we offer high-performance Cellular Glass Insulation solutions that are specifically developed to offer thermal insulation, moisture resistance, and mechanical strength for multiple manufacturing and commercial applications.

Cellular Glass insulation is manufactured from millions of hermetically sealed cells of glass and offers incredible dimensional stability, is non-combustible, and has 0 permeance to water vapor, making it a great and chemically stable product for challenging thermal insulation conditions — in HVAC applications, cryogenic pipeline systems, and chemical processing facilities are examples of these types of installations.

What Is Cellular Glass Insulation?

Cellular Glass is a rigid, lightweight, closed-cell insulation material made from carbon and crushed glass. It has the strength of a structural material and the thermal performance of an insulating material.

Cellular Glass does not absorb moisture, support mold growth, or degrade over time, and performs exceptionally well for both hot and cold service. You cannot use more highly engineered insulation material than Cellular Glass.

Key Features

- No Water Absorption – 100% closed-cell means you can plan for performance in humid environments or submerged conditions.

- Reliable Fire Resistance – Non-combustible, rated as Class A1 according to EN standard.

- High Thermal Performance – Low thermal conductivity makes it a thermally efficient material for energy savings.

- High Compressive Strength – Industrial applications tend to be mechanically destructive; Cellular Glass is resistant to mechanical degradation in industrial applications.

- Chemical & Biological Inertness – Non-reactive to acids, pests, fungi, or rodents.

- Sustainable & Non-Toxic – Environmentally friendly and recyclable insulation solution.

Available Forms & Technical Specifications

Cellular Glass Boards / Slabs

- Thickness Range: 25 mm to 180 mm

- Density: Approx. 115 kg/m³ (±10%)

- Applications: Flat surfaces, tank bases, vessel heads, cold storage floors, equipment panels

Pipe Sections

- Diameter Range: ½ inch to 24 inches

- Thickness Range: 25 mm to 100 mm

- Density: 115 kg/m³ (±10%)

- Applications: Chilled water lines, cryogenic pipelines, high-temp process piping, LNG systems

Curved or Custom Shapes

- Custom Fabrication: Slabs can be cut and shaped into curved, conical, or angular segments

- Density: 115 kg/m³ (±10%)

- Use Case: Fittings, elbows, tees, reducers, complex geometries in duct and pipe systems

Fabrication Capabilities

Nextera offers in-house precision cutting and fabrication services using advanced cellular glass blocks supplied by global leaders. Our fabrication unit ensures exact sizing, faster project turnaround, and reduced material waste – helping contractors meet site-specific insulation demands with confidence.

Ideal for Critical Applications

- Petrochemical & Power Plants

- LNG & Cryogenic Installations

- Pharmaceutical & Food Processing

- Cold Chain Infrastructure

- Substation & HVAC Equipment

- Offshore & Marine Facilities

Standards & Compliance

- ASTM C552 – Cellular Glass Thermal Insulation

- EN 13501-1 – Euroclass A1 Fire Classification

- FM Approved – Non-combustible insulation for fire-sensitive areas

What Makes Nextera the Preferred Choice of Clients?

- Proven Experience: Extensive technical expertise with industrial insulation across the UAE and other international markets.

- Registration with a Local Fabrication Shop: This leads to a quicker turnaround time, custom sizing, and less time wasted on a project.

- Registered Product Quality: Some branded products on the market to consider.

- Sustainability: Long-term access to an environmental and operational benefit with Nextera products.

- Access to Technical Support: Selecting specs to on-site install assistance with our team to ensure project success every time.

Frequently Asked Questions

1. What is Cellular Glass Insulation and where is it used?

Cellular Glass is a rigid, closed-cell insulation material made from crushed glass and carbon. It is commonly used in HVAC systems, cryogenic pipelines, LNG facilities, petrochemical plants, cold storage, and marine installations due to its exceptional thermal efficiency, durability, and moisture resistance.

2. Is Cellular Glass Insulation fire-resistant?

Yes. Cellular Glass is completely non-combustible and certified as Euroclass A1 under EN 13501-1. It does not burn, melt, or release toxic smoke, making it ideal for fire-sensitive environments like power plants, substations, and chemical facilities.

3. Does Cellular Glass absorb water or moisture?

No. Cellular Glass has a 100% closed-cell structure with zero water vapor permeance. It does not absorb moisture or allow condensation, making it suitable for humid, wet, or submerged conditions, such as cold storage floors and cryogenic applications.

4. How strong and durable is Cellular Glass?

Cellular Glass is known for its high compressive strength, which allows it to withstand heavy industrial loads without deformation. It is also resistant to chemicals, acids, fungi, rodents, and pests, ensuring long-term durability in demanding environments.

5. What forms of Cellular Glass Insulation are available?

Cellular Glass comes in different forms to suit project needs:

- Boards/Slabs – for flat surfaces, tank bases, and equipment panels.

- Pipe Sections – for chilled water lines, LNG pipelines, and high-temperature piping.

- Custom Shapes – for elbows, tees, reducers, and complex duct or pipe geometries.

Get in Touch

Looking for technically sound and environmentally friendly cellular glass insulation?

Call: +971 4 2633071

Email: sales@nexterainsulations.com

Visit: www.nexterainsulations.com

Enquire Now

Have Questions or Ready to Get Started? Reach Out to Us Today — We're Here to Help!